They work predominantly in the Asian region, mainly Thailand, with a considerable market share. Maxidive is at the forefront of using techniques and equipment to make the job more environmentally friendly, value for money, and give the client a hassle-free service.

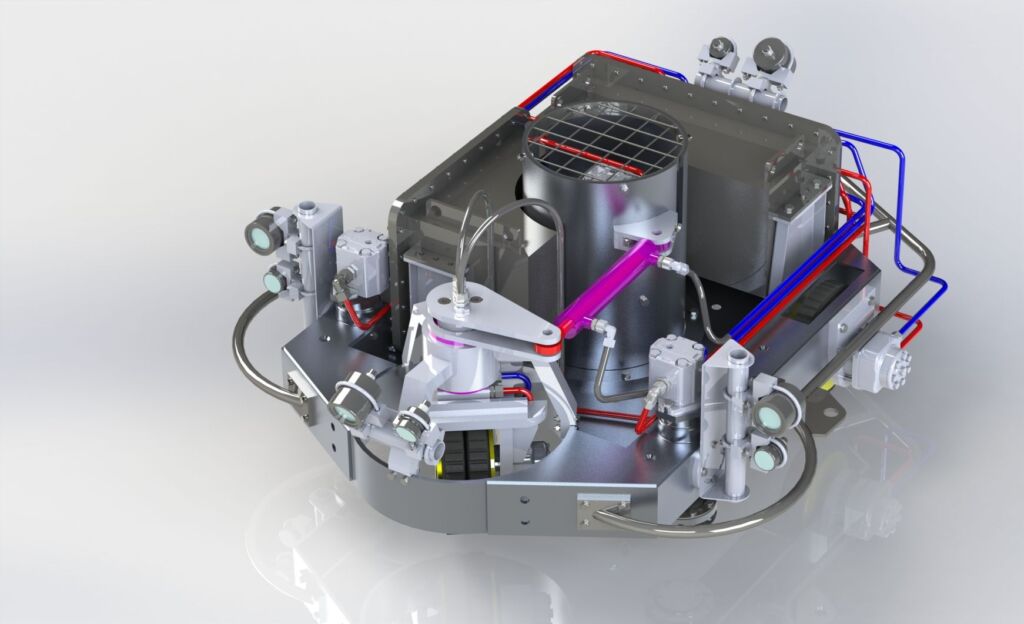

The emphasis is on creating a more environmentally friendly service that has a little operational impact on the customer. Maxidive has developed a revolutionary hull cleaning system with their partners in Europe. Pictured below, the Hull Cleaning Automated ROV System will be more cost-effective and allow cleaning within the port limits with 100% safety guaranteed and focus on preserving the vessel’s antifouling coating!

with the latest cleaning machine PROMAX MP II with an integrated central turbine that uses the only new generation of rubber base brushes (effective and more gentle to antifouling coating).

Our operators have more than ten years of experience in ship cleaning services. MAXIDIVE follows all the latest recommendations and guidelines provided by manufacturers of antifouling coating: HEMPEL, JOTUN, KANSAI AKZO NOBEL, BOERO, EVONIK, DuPONT, KANSAI PAINTS, INTERNATIONAL.

Most of the commercial diving companies are offering propeller polishing to the grade “A” Rupert scale, which is = < 0.65 microns. Because the propeller is mostly made from a nonferrous material, there is close to impossible to verify achieved surface roughness after polishing. The exception is visual evaluation comparing the surface with Rubert’s sample plate.

- MAXIDIVE uses a multi-stage propeller polishing process with the latest tools and materials (3M).

- The benefits of a clean propeller with minimum surface roughness are not a secret to the shipping industry.